It’s signage that uses built-in lighting-LEDs, neon or fluorescent-to make letters, logos and graphics visible day and night. You can choose backlit channel letters, lightboxes or digital displays; each option differs in brightness, energy use, maintenance and cost. Understanding these basics helps you select the right illuminated sign for visibility, branding and regulatory requirements.

Key Takeaways:

- Illuminated signs are signs with built-in lighting (LED, neon, or fluorescent) that make text or graphics visible at night and in low light.

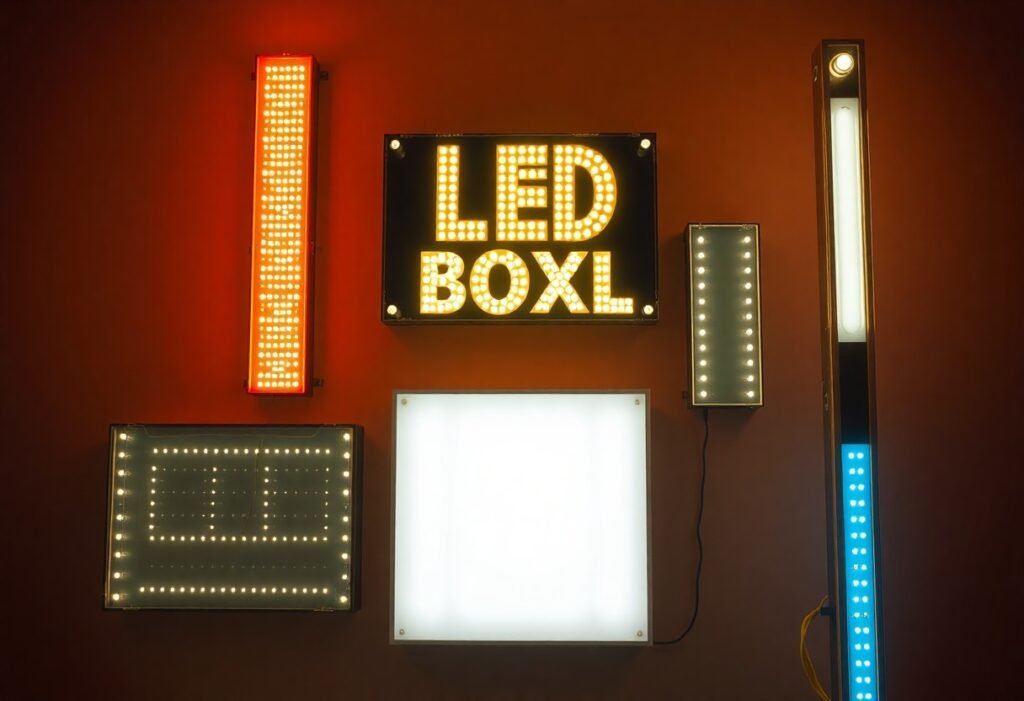

- Common types include channel letters, lightboxes, neon tubes, and LED displays, each using different lighting and construction styles.

- Main benefits are improved visibility, stronger branding, and easier wayfinding compared with unlit signs.

- Basic components are a light source, face or letters, housing/frame, and power supply or driver.

- Consider energy use, weatherproofing, local sign regulations, and periodic maintenance when choosing and installing one.

What are Illuminated Signs?

Definition and Purpose

You see illuminated signs daily; they integrate internal light sources-LEDs, neon, or fluorescent-to keep text and graphics readable after dark and in low light. They attract attention, extend business hours visibility, and reinforce brand identity; studies report lit storefronts can increase evening foot traffic by 20-30%. When you specify a sign, weigh brightness (lumens), color temperature (3000-6000K), mounting height, and expected viewing distance to meet your visibility goals.

Types of Illuminated Signs

Channel letters, lightboxes, neon tubing, backlit push-through letters, and digital LED displays each serve distinct applications: channel letters for storefront presence, lightboxes for large logo panels, neon for vintage color, backlit for halo effects, and digital for dynamic messaging. Channel-letter depth and LED density affect legibility at 50-200 m; lightboxes commonly use 400-2,000 lux. Knowing the trade-offs in brightness, cost, and maintenance helps you pick the right option.

- Channel letters – individual illuminated letters, high visibility for street-level signage.

- Lightbox (box sign) – large face panels ideal for bold logos and uniform illumination.

- Neon tubing – glass tubes with vibrant color, often used for retro or decorative looks.

- Backlit (halo) letters – subtle glow from the rear for premium branding effects.

- Digital LED displays – programmable screens for changing messages and video.

| Channel letters | Best for storefronts; readable up to 150-200 m with proper sizing; LED lifespan ~50,000 hrs. |

| Lightbox | Large, uniform panels; common for malls; typical face luminance 400-2,000 lux. |

| Neon | High color saturation and vintage appeal; lifespan 8,000-15,000 hrs; higher maintenance. |

| Backlit letters | Creates halo effect; used for premium branding; lower direct glare than front-lit options. |

| Digital LED | Programmable content and animation; higher power draw; ideal for frequent updates. |

Beyond style, power draw, lifespan, and local rules shape long-term value: LEDs typically run 50,000+ hours and cut energy 50-70% versus neon, while neon lasts 8,000-15,000 hours and needs more upkeep. You should check municipal brightness limits-many zones cap signage at ~200-300 cd/m²-and factor installation and permit costs into ROI; a recent retail LED retrofit reduced sign energy by ~60% with a 2-4 year payback. Knowing how energy, maintenance, and regulation interact informs your final specification.

- Energy & lifespan – choose LEDs for long life and lower operating cost.

- Maintenance – plan access for bulb/driver replacement and cleaning every 6-18 months.

- Permits & codes – verify local luminance limits and setback requirements before ordering.

- Brightness & placement – match lumens to viewing distance (e.g., larger signs for >50 m).

- Installation & ROI – compare upfront vs. lifetime costs; retrofits often pay back in 2-4 years.

| Consideration | Recommended action for you |

| Power consumption | Select high-efficacy LEDs and estimate annual kWh to model costs |

| Lifespan | Specify LEDs (~50,000 hrs) for lower replacement frequency |

| Local regulations | Obtain permits early and confirm max brightness and operating hours |

| Maintenance access | Design for easy access to drivers, lamps, and wiring to reduce service time |

| Visual impact | Balance color temperature and lumen output to match brand and viewing distance |

Components of Illuminated Signs

You’ll encounter five core elements: light sources, the face or lens, cabinet/returns, power supply/drivers, and mounting hardware. LEDs or neon sit behind acrylic, metal, or vinyl faces; cabinets typically range 75-200 mm deep for lightboxes and 75-150 mm for channel letters. Controllers add animation or dimming, while seals, vents and thermal management protect electronics and extend service life.

Light Sources

LEDs dominate with 50,000-100,000 hours life and 80-150 lm/W efficiency, supporting RGB color mixing, dimming and low-profile modules. Fluorescent tubes give even backlight but age around 10,000-20,000 hours and need ballasts. Neon provides vivid, saturated colors and can last 15,000-50,000 hours when maintained. Fiber optic is used for pinpoint or routed effects with centralized light engines.

Sign Materials

Acrylic (PMMA) is the typical face material-opal grades diffuse LEDs evenly and are commonly 3-6 mm thick; aluminum returns (1-3 mm) form the cabinet. Polycarbonate offers superior impact resistance for high‑risk locations, while stainless steel or powder‑coated aluminum create premium exteriors. Translucent or blockout vinyl controls daytime legibility, with outdoor-grade films typically lasting 3-7 years.

For durability choose UV‑stabilized acrylic to retain clarity 10+ years; edge‑lit panels work best at 10-20 mm thickness for uniform glow. Polycarbonate resists impact but needs UV treatment to avoid yellowing. Specify IP65 gaskets and pressure‑equalization vents to prevent condensation, allow slotted fasteners for thermal expansion, and consider powder coatings or anti‑graffiti laminates to simplify maintenance and repaint cycles.

Benefits of Illuminated Signs

Beyond aesthetics, illuminated signs extend your message around the clock, improving wayfinding and boosting perceived professionalism; LEDs typically use 50-75% less energy than neon or fluorescent and last 5-10 times longer, lowering lifetime costs and maintenance visits for your storefront or office façade.

Visibility and Awareness

Nighttime legibility improves markedly: use the rule of thumb-1 inch of letter height per 10 feet of readability-so a 36‑inch letter can be seen from roughly 360 feet, helping you capture passing traffic. You can choose backlit channel letters or edge‑lit panels to stand out on busy corridors, and continuous illumination keeps your location top‑of‑mind during evening shopping and late‑shift hours.

Branding and Advertising

Illuminated signs strengthen your brand with consistent color temperature and controlled luminance; you can employ color‑matched RGB LEDs for brand palettes or deploy high‑resolution LED panels to run promotions, enabling frequent message rotation without print costs-many retailers schedule new creatives every 15-30 seconds to maximize impressions.

For deeper impact, you can tailor display content by time of day-bright, cool whites for morning commuters and warmer tones for evening diners-and run A/B tests over 7-14 day periods to find the highest‑performing creatives; adding QR codes or short URLs on illuminated panels lets you attribute responses and measure conversion lift directly.

Applications of Illuminated Signs

You’ll find illuminated signs everywhere because they extend visibility and brand impact past daylight hours; LEDs often last 50,000-100,000 hours and provide 24/7 visibility for storefronts and landmarks. You can explore real-world Benefits of Illuminated Signs such as improved evening foot traffic and clearer brand recognition in dense retail corridors.

Commercial Use

Retailers, restaurants, gas stations and hotels use illuminated channel letters, lightboxes and pylon signs so your location is visible from the street at night; franchises often standardize signage across 10-100+ sites for brand consistency. You’ll see LED backlit letters deliver bright, even illumination with lower energy use than neon, and service businesses commonly report stronger customer recall after upgrading to illuminated facades.

Directional and Informational Use

Airports, hospitals and campuses rely on illuminated wayfinding and exit signs so your guests and staff navigate quickly; emergency fixtures typically include battery backup to keep signs lit during outages, and digital message centers update real-time information like gate changes or parking availability.

For more detail, you’ll notice outdoor LED wayfinding can range 2,000-7,000 nits for daylight readability, while indoor digital kiosks use full-color panels to display schedules and maps; hospitals often color-code illuminated directional signs to reduce confusion, and universities deploy 6-12 ft pylons along arterial roads to guide visitors from a distance.

Installation and Maintenance

When you schedule installation, plan for site surveys, permits, and electrical hookups; simple wall-mounted LED signs often take 2-6 hours, while rooftop or highway-facing builds can require days plus structural engineering and wind-load calculations. You should expect permit fees commonly between $50-$500 depending on jurisdiction, and coordinate with an electrician for a dedicated circuit and GFCI protection to meet local code and ensure long-term reliability.

Installation Process

You begin with a site survey to verify measurements, mounting substrate, and power access, then fabricate brackets and run conduit; a crew of 2-4 technicians will anchor the sign, connect the driver and power, seal all penetrations, and perform photometric and safety tests. For example, a 6ft channel letter set typically requires 4-6 anchor points and a final lux reading to confirm uniform illumination.

Maintenance Best Practices

You should clean faces every 3-6 months with a mild detergent and soft cloth, inspect seals and gaskets annually for moisture ingress, and log driver and LED module performance; LEDs typically last ~50,000 hours, so plan driver replacement or warranty checks around 5-7 years. Also schedule an annual electrical inspection to catch loose connections and corrosion before outages occur.

For additional reliability, implement a preventive maintenance checklist: photograph each sign, record lumen output and color consistency, and replace aging components proactively. If you manage multiple locations, quarterly checks cut reactive repairs-one 50-location franchise reduced sign outages by about 60% after switching to a quarterly inspection and parts-replacement schedule. Avoid pressure washing and use industry-grade sealants on any reopened enclosures to maintain IP ratings.

Regulations and Guidelines

Local Regulations

If you plan an illuminated sign, check municipal sign codes and zoning: many cities limit sign area to 10-20% of a façade, ban dynamic lighting in historic districts, and cap luminance (often 300-500 cd/m² or 5-20 foot‑candles). Permit fees typically run $50-$500 and approval can take 2-8 weeks. Examples like New York City and San Francisco impose strict preservation-area controls, and noncompliance can lead to removal orders or fines.

Safety Standards

NEC Article 600 governs electric signs in the US and UL 48/UL 8750 cover sign construction and LED equipment, so you must use UL‑listed components and follow NEC wiring, grounding, and disconnect rules. Outdoor fixtures generally require IP65 or better, surge protection, and adequate thermal management; installers usually need to be licensed electricians to avoid fire hazards and liability.

You should schedule annual inspections and perform connection tests because typical LEDs are rated 30,000-50,000 hours while drivers often fail sooner; plan to replace drivers every 5-7 years or when output drops below 70%. Keep records of insulation resistance and polarity checks, specify IP/UL ratings in purchases, and note that proactive driver replacement has reduced outages by roughly 80% in some retail rollouts.

Summing up

On the whole, illuminated signs are lighting-enhanced displays that make your brand visible day and night; they combine a face, frame and an internal or external light source-LED, neon or fluorescent-to convey messages clearly, boost wayfinding and attract customers, and you should choose materials, brightness and installation that suit your location, budget and safety needs.

FAQ

Q: What are illuminated signs explained in simple terms?

A: Illuminated signs are signs that light up so they can be seen clearly at night or in low light. They combine a light source (like LEDs, neon, or fluorescent tubes) with a sign face to make letters, logos, or symbols glow and stand out.

Q: How do illuminated signs work?

A: A light source is placed behind, inside, or around the sign face; a translucent or reflective surface spreads the light to form readable shapes and colors. The system includes wiring and a power supply or driver, and may use diffusers or lenses to achieve even illumination.

Q: What common types of illuminated signs exist?

A: Common types include channel letters (individual lit letters), lightboxes/backlit panels, neon tubing signs, and LED displays. They differ in appearance, brightness, energy use, lifespan, and cost-LEDs are energy-efficient, neon gives a classic glow, and lightboxes offer large, even illumination.

Q: Where are illuminated signs typically used?

A: They are used for storefronts, building facades, billboards, interior wayfinding, and event signage to improve visibility, attract attention, and convey information day and night. Outdoor models are weatherproofed; indoor versions focus on design and visibility in interior lighting conditions.

Q: What should be considered for installation, maintenance, and safety?

A: Installation often requires secure mounting and proper electrical connections, so a licensed electrician or professional sign installer is recommended. Maintenance includes cleaning faces, checking seals and wiring, and replacing failed lights or drivers. Ensure compliance with local electrical codes and any permitting requirements for outdoor signs.